In today’s sustainability-conscious market, corporate environmental pledges are common. However, transforming those pledges into a tangible, operational business model is where true leadership emerges. LG Electronics is making this shift, moving beyond incremental efficiency gains to embed a circular economy framework into its core product strategy. This isn’t just about recycling; it’s a fundamental rethinking of design, materials, and product life cycles from start to finish.

Understanding the Circular Economy Model

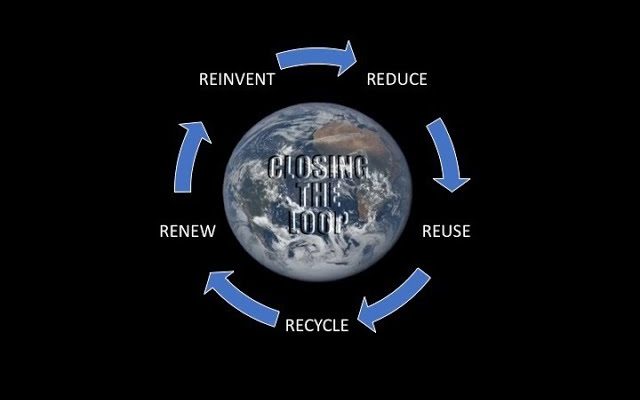

Unlike the traditional “take-make-dispose” linear model, a circular economy aims to eliminate waste and continuously reuse resources. According to the Ellen MacArthur Foundation, a leading global thought leader on the topic, it is based on three principles: designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. For a manufacturing giant like LG, this represents a significant pivot from how products have been made for decades.

LG’s Strategy: From Recycled Plastics to Full-Lifecycle Design

LG’s approach is multifaceted, targeting both the beginning and end of a product’s journey.

-

Closing the Material Loop with PCR Plastics:

A cornerstone of LG’s strategy is the aggressive integration of Post-Consumer Recycled (PCR) plastics. The company has set public targets, aiming to use 600,000 tons of recycled plastic by 2030. This material, sourced from discarded electronics, bottles, and other waste streams, is now found in everything from the inner liners of LG refrigerators to the outer cabinets of LG washing machines and TV stands. This directly reduces reliance on virgin fossil-fuel-based plastics and diverts waste from landfills. -

Designing for Disassembly and Repair:

True circularity requires products that are built to last and be repaired. LG has invested in modular design for easier disassembly, a practice highlighted by repair advocates like iFixit as critical for extending product lifespans. Furthermore, their focus on core component durability—like the Inverter Compressor with a 20-year warranty—ensures longer use phases, which is the most sustainable option of all. -

Responsible End-of-Life and Take-Back Programs:

Closing the loop requires responsible product retirement. LG operates e-waste recycling programs in numerous countries, partnering with certified recyclers to recover valuable materials. They also engage in refurbishment initiatives, giving functional yet older appliances a second life, a model gaining traction across the tech industry as reported by platforms like The Verge.

Case Study: The Sustainable Home Appliance

This strategy comes to life in specific products. For instance, many 2023 LG refrigerators incorporate PCR materials in both interior and exterior components, utilize highly efficient linear compressors to reduce energy consumption, and are designed with recyclability in mind. This creates a product that has a lower carbon footprint at birth, operates efficiently for years, and is more responsibly managed at its end-of-life.

The Broader Impact and Industry Challenge

LG’s commitment signals a broader shift in the electronics sector. By investing in recycled material supply chains, they help scale a market for PCR plastics, making it more viable for the entire industry. However, challenges remain, including the technical performance of recycled materials, complex global recycling infrastructures, and consumer education on proper e-waste disposal.

Looking Ahead: The Circular Future

LG’s journey reflects an understanding that future competitiveness is tied to sustainable innovation. As regulatory pressures increase—such as the European Union’s right-to-repair legislation—and consumer preferences evolve, a circular model transitions from a commendable initiative to a business imperative. LG’s progress demonstrates that for global corporations, environmental stewardship and industrial leadership are no longer separate paths, but a single road forward.